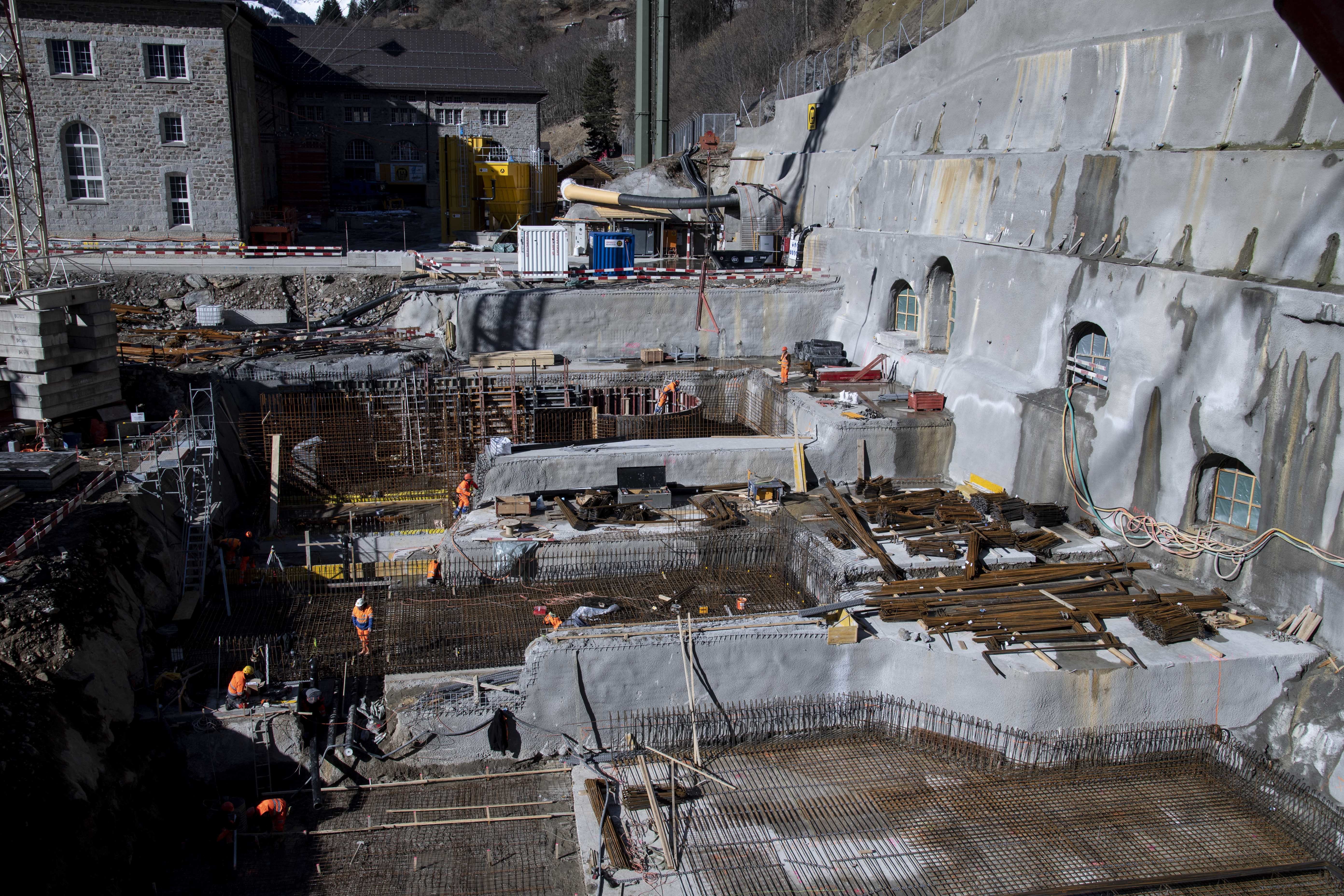

New construction of the historic hydroelectric power plant Ritom

Environmentally friendly power generation

«The new construction of the Ritom hydroelectric power plant is of prime importance for Ticino and the north-south axis of the Swiss Federal Railways. In addition to increasing capacity, special emphasis was placed to environmental protection.»

There is no modern railway without electricity. This was true already over 100 years ago. As early as 1917, the Ritom hydroelectric power plant in the canton of Ticino supplied electricity for the first time to trains travelling through the Gotthard on the north-south axis. As the power plant has lost none of its importance to this day, the renewal request of the concession by Swiss Federal Railways SBB and Azienda Elettrica Ticinese AET for the utilisation of Ticino's waters was approved for a further 80 years in 2012. The new hydropower plant will replace the existing one from 1917 and will have two turbines and a pump with a capacity of 60 megawatts each.

The power plant's ability to respond quickly to changes in electricity demand is particularly important for grid stability and plays a balancing role in the variability of renewable energy sources such as wind and solar energy. This contributes significantly to the stability, reliability, and efficiency of the energy system. As a member of the engineering Consortium Ritom Ticino CRT, Lombardi is responsible for all general planning tasks - from the construction project through to commissioning. In this challenging construction project, we were able to benefit from our extensive expertise in the field of power plants and tunnelling. The work was particularly challenging due to the intrusion of mountain water. However, thanks to special injections and the great commitment of the miners, the rock was sealed.

It is not only the generation of electricity at the Ritom hydropower plant that will be sustainable in the future - great importance was also attached to environmental compatibility in other aspects of the project. Rapid changes in water levels due to turbines, which could cause problems for flora and fauna, are a thing of the past. The equalisation basin serves to protect nature in the river. The Ritom power plant thus demonstrates that electricity generation from hydropower and environmental protection go hand in hand.

- Conventional and TBM tunnelling

- Cavern and shaft construction

- Underground facilities and systems

- Ventilation

- Technical buildings

- Renovation

- Excavation support and ground improvement

- Hydroelectric power plants

- Surface and underground powerhouses

- Hydraulic tunnels and shafts

- Penstocks and steel lining

- Hydromechanical equipment

- Electromechanical equipment

- Balance of Plant

- Water transfer systems and pumping stations

- River engineering

- Hydrology and watershed modelling

- Material Management

- Special geotechnical works

Metres - gradient level between Lake Ritom and the Piotta hydropower station

Cubic metres - Capacity of the compensation basin

Kilometres - Length of adduction tunnel with penstock and inclined shaft

Million cubic metres - average volumetric capacity of Lake Ritom

Lat: 46.517

Lng: 8.677

Ritom

«The mountain water intrusion in the tunnel posed particular challenges that we were only able to overcome thanks to the commitment of everyone involved. This makes the completion of the Ritom hydropower plant even more gratifying. The project is a prime example of sustainable energy production.» Daniele Bronzetti